您所在的位置:首页 - 生活 - 正文生活

托盘机器人

![]() 芯然

2024-05-14

【生活】

636人已围观

芯然

2024-05-14

【生活】

636人已围观

摘要**Title:UnlockingEfficiencyandPrecision:MachineTrayProgramming**Intherealmofindustrialautomation,mac

Title: Unlocking Efficiency and Precision: Machine Tray Programming

In the realm of industrial automation, machine tray programming stands as a pivotal technique for optimizing efficiency, enhancing precision, and streamlining processes. This innovative approach involves the utilization of software and algorithms to dictate the movements and actions of machine trays within manufacturing and logistics environments. Let's delve into the intricacies of machine tray programming, exploring its significance, key principles, and potential applications.

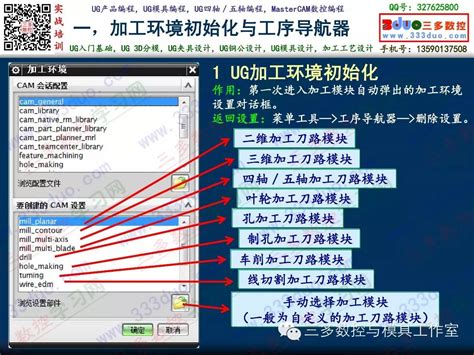

Understanding Machine Tray Programming

At its core, machine tray programming revolves around the development of algorithms that govern the behavior of trays or pallets within automated systems. These trays, often equipped with sensors and actuators, can perform a myriad of tasks, including transportation, sorting, stacking, and loading/unloading. By orchestrating the movements of these trays with precision, businesses can achieve notable enhancements in productivity, reliability, and costeffectiveness.

Key Components and Techniques

Machine tray programming typically encompasses several essential components and techniques:

1.

Motion Planning

: This involves determining the optimal trajectory for trays to navigate within a designated workspace while adhering to safety constraints and operational requirements. Techniques such as path planning algorithms, including A*, Dijkstra's algorithm, or Rapidlyexploring Random Trees (RRT), are commonly employed to facilitate efficient motion planning.2.

Collision Avoidance

: To ensure smooth and uninterrupted operation, algorithms are implemented to detect and avoid collisions between trays, machinery, and obstacles. Collision avoidance strategies may involve realtime monitoring, predictive analytics, or the integration of sensors such as LiDAR or computer vision systems.3.

Task Scheduling

: Effective task scheduling algorithms allocate tasks to trays in a manner that optimizes overall system throughput and minimizes idle time. Techniques like prioritybased scheduling, dynamic task allocation, and preemptive scheduling algorithms contribute to enhanced operational efficiency.4.

Integration with Manufacturing Execution Systems (MES)

: Seamless integration with MES enables realtime data exchange, enabling machine tray programming systems to adapt to changing production demands, inventory levels, and quality control requirements.Applications Across Industries

The versatility of machine tray programming renders it applicable across a diverse range of industries, including:

1.

Automotive Manufacturing

: In automotive assembly plants, machine trays facilitate the transportation of components, subassemblies, and finished products along the production line, contributing to JustInTime (JIT) manufacturing and flexible production processes.2.

Ecommerce and Logistics

: Within distribution centers and warehouses, automated guided vehicles (AGVs) equipped with machine trays autonomously navigate storage aisles, retrieve items, and fulfill orders, bolstering order fulfillment speed and accuracy.3.

Food and Beverage

: In food processing facilities, machine trays aid in the handling and packaging of perishable goods, optimizing inventory management and ensuring compliance with food safety regulations.4.

Pharmaceuticals

: Machine tray programming plays a crucial role in pharmaceutical manufacturing, facilitating the precise handling and transport of delicate ingredients, intermediates, and final products while maintaining stringent quality control standards.Guiding Principles for Implementation

Successful implementation of machine tray programming hinges upon adherence to several guiding principles:

1.

Modularity and Scalability

: Design systems that are modular and scalable, allowing for seamless integration of additional trays, machinery, and functionalities as operational requirements evolve.2.

Reliability and Fault Tolerance

: Incorporate redundancy and error recovery mechanisms to mitigate the impact of equipment failures or malfunctions, ensuring continuous operation and minimal disruption to production.3.

HumanMachine Interaction (HMI)

: Develop intuitive user interfaces that enable operators to monitor system performance, intervene when necessary, and configure parameters with ease, promoting user acceptance and operational efficiency.4.

Continuous Improvement

: Embrace a culture of continuous improvement by leveraging data analytics and feedback mechanisms to identify bottlenecks, optimize algorithms, and enhance overall system performance over time.Conclusion

In conclusion, machine tray programming represents a cornerstone of modern industrial automation, offering unparalleled opportunities for enhancing efficiency, precision, and adaptability across various sectors. By leveraging advanced algorithms, robust hardware, and seamless integration with existing infrastructure, businesses can unlock new levels of productivity and competitiveness in an increasingly dynamic and demanding marketplace.

Tags: 恐龙特攻队 英雄联盟厄加特 口袋精灵游戏 河原崎家的一族

版权声明: 免责声明:本网站部分内容由用户自行上传,若侵犯了您的权益,请联系我们处理,谢谢!联系QQ:2760375052