您所在的位置:首页 - 百科 - 正文百科

三轴编程是什么

![]() 晔涵

2024-04-24

【百科】

660人已围观

晔涵

2024-04-24

【百科】

660人已围观

摘要ComparisonofThree-AxisandFive-AxisProgrammingComparisonofThree-AxisandFive-AxisProgrammingThree-axis

Comparison of ThreeAxis and FiveAxis Programming

Threeaxis and fiveaxis programming are essential concepts in the field of computer numerical control (CNC) machining. Both techniques are used to control the movements of cutting tools to create precise and complex parts. Let's explore the differences between these two methods:

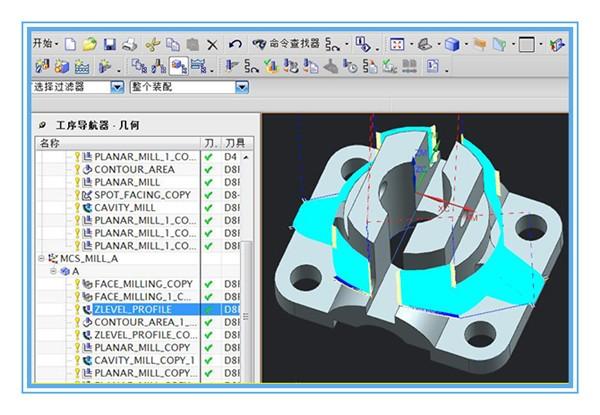

In threeaxis programming, the CNC machine operates along three axes: X (horizontal), Y (vertical), and Z (depth). This programming method is suitable for machining relatively simple and flat parts that do not require intricate geometries or complex tool orientations.

Key features of threeaxis programming:

- Suited for basic machining operations.

- Works well for parts with simple geometries.

- Straightforward tool paths along three primary directions (X, Y, Z).

- Commonly used in industries such as woodworking, prototyping, and general manufacturing.

Fiveaxis programming extends the capabilities of CNC machining by adding two rotational axes to the three linear axes. This allows the cutting tool to approach the workpiece from multiple angles, enabling the production of highly complex and precise components.

Key features of fiveaxis programming:

- Offers greater flexibility in tool movement.

- Enables machining of complex geometries, such as turbine blades and impellers.

- Reduces setup times by machining multiple surfaces in one operation.

- Requires specialized CAM (computeraided manufacturing) software for efficient programming.

- Commonly used in aerospace, automotive, and medical industries for advanced part manufacturing.

| Aspect | ThreeAxis Programming | FiveAxis Programming |

|---|---|---|

| Complexity of Parts | Best suited for simple to moderately complex parts. | Ideal for highly complex and intricate parts. |

| Tool Maneuverability | Tool movement limited to three axes. | Tool can approach the workpiece from multiple angles, offering enhanced maneuverability. |

| Setup Time | May require more setups for complex parts. | Reduces setup time by machining multiple surfaces in one operation. |

| Software Requirements | Can use standard CAM software. | Requires specialized CAM software capable of handling multiaxis operations. |

| Industry Applications | Common in woodworking, prototyping, and general manufacturing. | Used extensively in aerospace, automotive, and medical industries. |

Choosing between threeaxis and fiveaxis programming depends on the complexity of the parts you need to manufacture and the specific requirements of your industry:

- For Simple Parts: Threeaxis programming is costeffective and efficient.

- For Complex Geometries: Opt for fiveaxis programming to achieve high precision and reduce production time.

- IndustrySpecific Needs: Evaluate which method aligns best with the demands of your industry.

- Software Considerations: Ensure your CAM software supports the required programming capabilities.

Ultimately, the choice between threeaxis and fiveaxis programming hinges on achieving the desired balance between part complexity, machining efficiency, and production costs.